How important a well-equipped finishing section for the Press?

A book’s journey from manuscript to finished product involves several critical stages, and among them, the finishing section is paramount. The finishing section is not just a stage in the process; it’s a hub of creativity and precision.

Role in Book Production

The finishing section is where the magic happens. It’s here that raw printed material transforms into the beautiful books we love to hold and read. This section handles the essential tasks of binding, trimming, and adding final touches that make each book unique. Whether it’s a hardcover book with a dust jacket or a simple paperback, the finishing section ensures the end product is durable, attractive, and ready to meet the readers’ expectations.

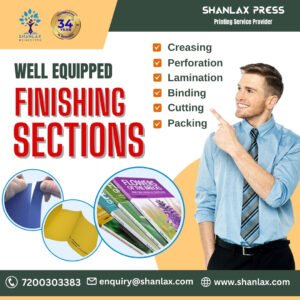

Key activities performed in the finishing section include:

– Binding: Whether it’s perfect binding, saddle stitching, or case binding, each type has its own set of equipment and expertise needed.

– Trimming and Cutting: Precision is key here. The final cut can make or break the presentation of a book.

– Lamination and Coating: Adding protective layers to ensure longevity and a premium feel.

Impact on Publishing Quality

The finishing section plays a pivotal role in defining the overall quality of a publication. A well-finished book is a testament to the publisher’s dedication to excellence. Here’s how a well-equipped finishing section impacts the publishing quality:

- Durability: Proper binding and finishing techniques ensure the book withstands the test of time, making it a valuable addition to any reader’s collection.

- Aesthetic Appeal: A beautifully finished book is not only a joy to read but also a delight to the eyes. It enhances the overall appeal and can significantly influence a buyer’s decision.

- Consistency: With advanced equipment, consistency in the quality of production across different batches is maintained, ensuring a uniform standard for every copy.

Influence on Market Reputation

A book that is well-produced speaks volumes about the publisher before even a single word is read.

Trust and Reliability

Competitive Edge

Positive Brand Image

Advanced Equipment Used in the Finishing Section

In the bustling world of publishing, Press stands out not only for its stellar content but also for its state-of-the-art finishing section.

Types of Machinery

Key machinery includes:

– Automated Binding Machines: These ensure that every book spine is tightly secured, offering both sturdiness and elegance.

– Precision Cutting Machines: With laser guides and ultra-sharp blades, these machines ensure that every page and edge is perfectly aligned.

– Laminating and Coating Machines: Adding the final protective layer to books, these machines provide both sheen and durability.

Technological Advancements

– Smart Automation: By leveraging automation, many tasks that previously required manual intervention are now done with unprecedented speed and accuracy.

– Digital Printing Technologies: With high-resolution digital printers, can produce vibrant colors and fine details, meeting the expectations of even the most discerning authors and publishers.

– Eco-friendly Solutions: Using advanced, environmentally sustainable inks and materials ensures that their processes do not harm the planet.

Benefits of Cutting-Edge Tools

Let’s look at the benefits that these cutting-edge tools bring:

– Consistency and Reliability: With advanced machinery, each book produced maintains the highest standards of consistency. There’s no wobble in quality, no room for error.

– Speed in Production: Tasks that used to take days can now be accomplished in hours, allowing for quicker turnarounds without sacrificing quality.

– Cost-Effectiveness: By optimizing processes through technology, and can keep costs competitive, making it an attractive choice for publishers on a budget.

Such benefits not only streamline operations but also significantly elevate the experience for authors and their audiences alike.

Enhancing Publishing Quality Through Advanced Tools

Through innovative tools, we ensure every book is a masterpiece.

Precision in Bookbinding

– Exact Spine Alignment: Ensuring pages sit flush against the spine, minimizing the risk of pages coming loose over time.

– Firm Adhesive Application: High-quality adhesives are evenly distributed, strengthening the bond without adding bulk.

This commitment to precision ensures that each book is not only pleasant to hold but also durable enough to withstand frequent handling.

Improved Durability and Aesthetics

A key focus for a Press is ensuring their books are as robust as they are aesthetically pleasing. Here’s how they achieve this:

– Enhanced Cover Resilience: By applying specialized coatings will increase the resistance to wear and tear, keeping them looking new for longer.

– Vibrant Printing: Advanced printers yield intense colors and sharp text, capturing the essence of any artwork or typography.

Add comment